After another full weekend of housework, errands, etc., I managed to fit in some work on the right tank’s inboard rib.

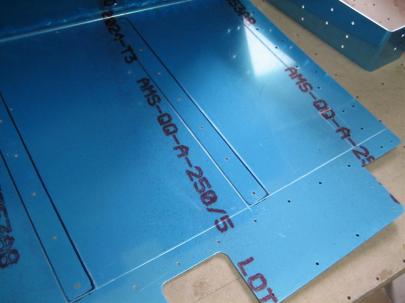

First thing, I fished out some parts. Here, Vans has punched out three parts, T-407 and T-410.

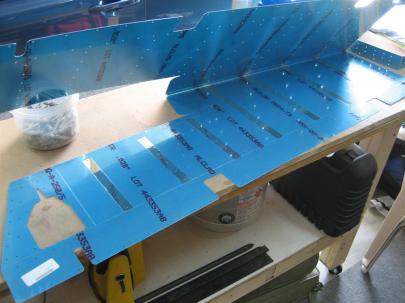

I decided to pull both assemblies(?) out and get them all deburred at the same time.

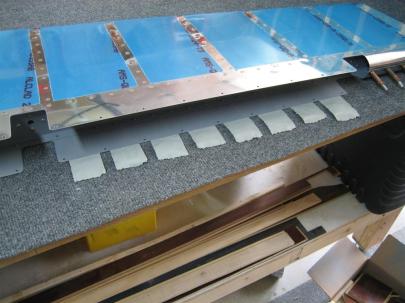

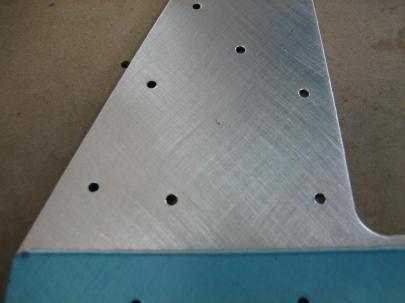

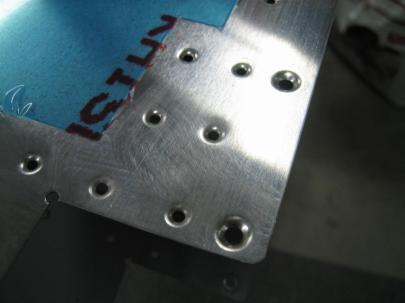

Here are the two access hole doubler rings and four rib reinforcement plates after deburring.

Then, I took one of the rings, centered it over the stiffener bump on the inboard rib, and used a straightedge to find the center of the circle.

I know I’m not really working on the left tank right now, but I decided that since I KNOW the circle cutter is going to be a PITA, I’ll just go ahead and do the left rib, too.

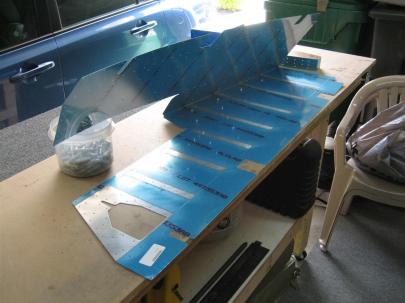

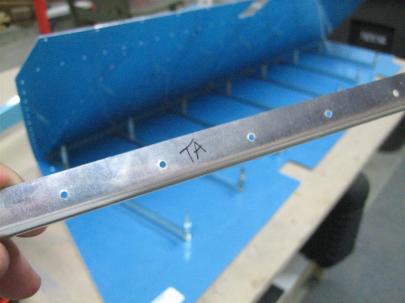

I fished out the two end ribs for the left tank and marked them so I knew which is which.

Before mounting the ribs up on the drill press, I needed to find some wood backing. How’s this tank-rib-shaped piece right here?

Whoa. That sucked. It sucked so bad, I didn’t even take any pictures. Among other things, the circle cutter 1) wouldn’t stay in one diameter, 2) shook so badly I thought my workbench was going to fall over, 3) almost killed me twice.

But, I finally managed to get a decent looking hole.

Oops, looks like the hole was a little big. No worries, edge distance for the rivets is just fine.

After some more cursing, cheating death, and general unhappiness, I managed to get a better (appropriately sized) hole on the left inboard rib.

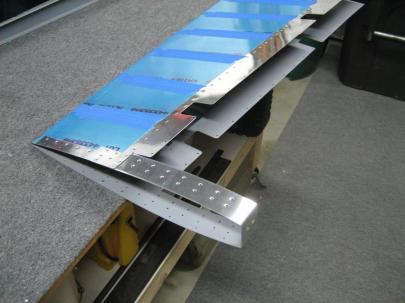

Okay, I’m straying from the instructions a little here. Normally, they want you to take this access cover, hold it against the rib, and use the prepunched #19 holes to drill holes in the rib. Then, hold the stiffener right aligned with those holes, and drill the nutplate attach rivet holes. Clear?

Instead, I’m going to eyeball the clocking of the access cover (so the flat part doesn’t interfere with the indentation in the rib), then just use the stiffener ring for all the drilling. (I need to order a new access cover with no holes in it because I’m using flop tubes (don’t need the small hole), which means I need to move the float sender to the second bay (don’t need the large hole).)

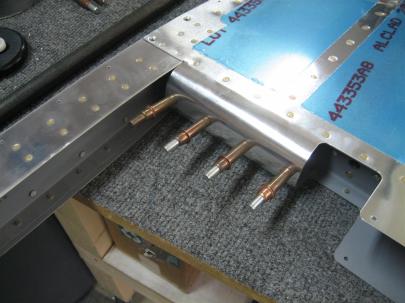

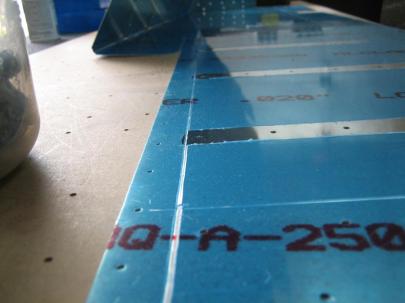

You can see in this picture, the stiffener ring is laid in place, and it looks like the access cover is clocked correctly.

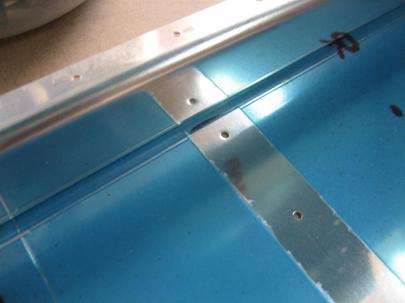

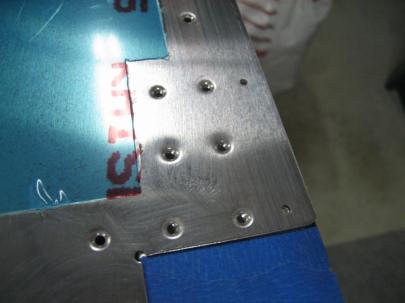

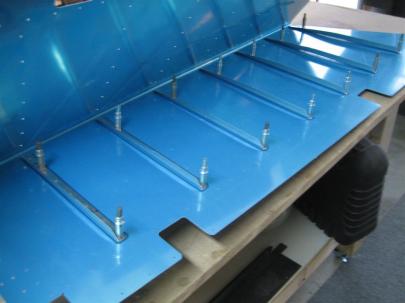

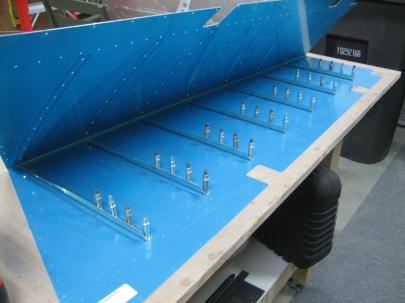

Here’s where things got frustrating. Because I wasn’t paying attention, I just started riveting the nutplates in place.

I drilled out six nutplates (didn’t enlarge any holes in the rib or stiffener), but couldn’t get the rivets out of the nutplates. They got THROWED AWAY!

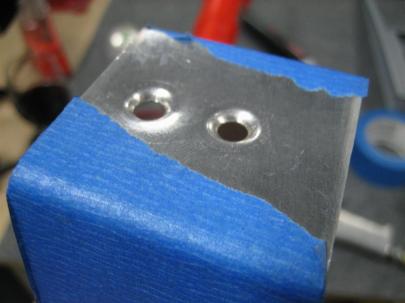

Okay, more countersinking, then try again. Still not deep enough? Ugh, more countersinking again, and finally, they were deep enough.

I got frustrated, so I stopped taking pictures. Sorry.

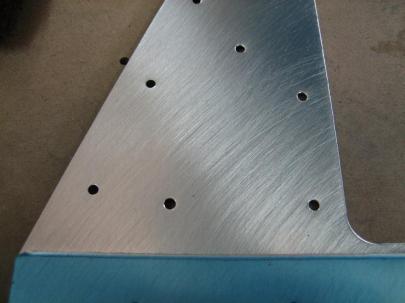

After much cursing and angry mumbling, I got all 24 rivets in for the 12 nutplates.

I had to drill out two more rivets because they were sitting a little proud. In the end though, I’m happy with the results.

24 rivets, 8 drilled out. (one third!? Ugh.)

2.0 glorious hours today.

Posted by Andrew

Posted by Andrew