Well, today was a crappy day. I had mucho problems with riveting the right rear spar to the main ribs.

I’ll walk you through what happened.

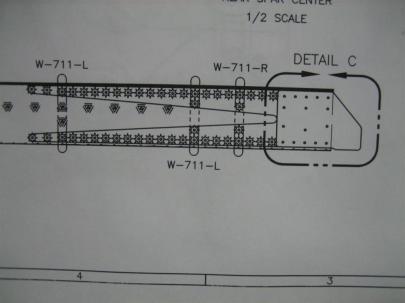

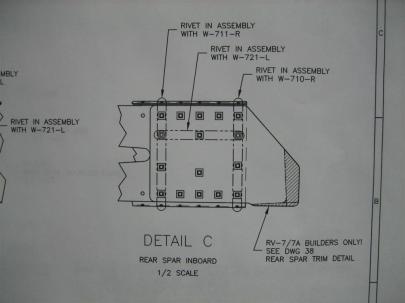

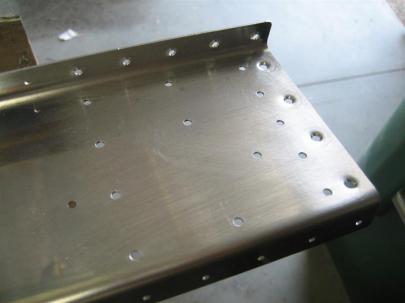

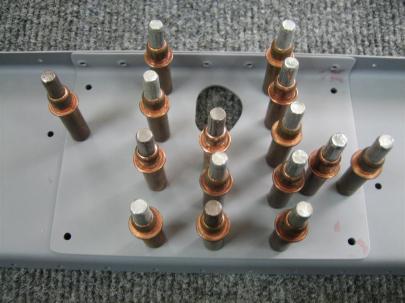

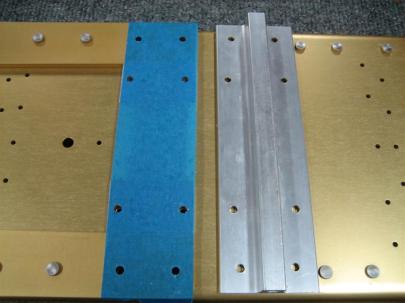

I started with the inboard side of the spar. The plans call for an AN470AD4-8 rivet. As you can see below, this is a little for a good shop head.

After some gymnastics with my good squeezer, which only has a 4″ no-hole yoke on it, I realized that I needed the holed yoke, and therefore needed to use my economy squeezer. Bummer.

(Back in the empennage, I stopped squeezing AD4 rivets altogether because I kept messing them up; the economy squeezer just didn’t have enough oompf.)

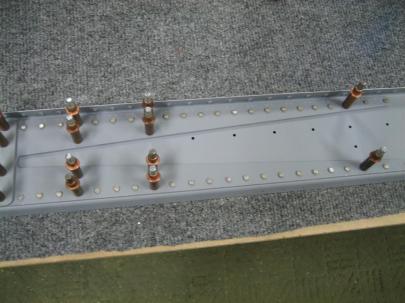

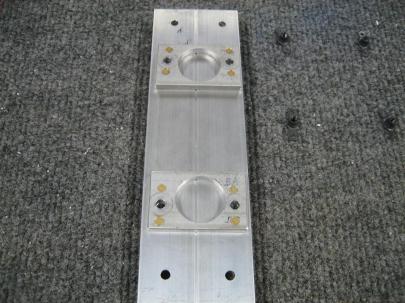

Anyway, I managed the wingwalk rivets with the smaller squeezer. Here’s 9 rivets squeezed.

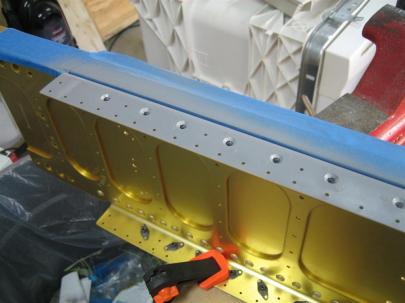

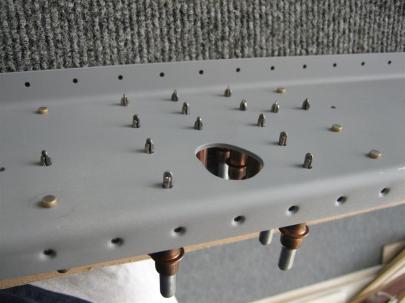

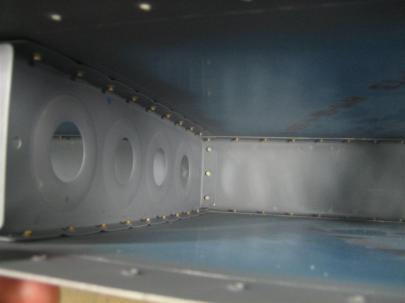

I couldn't reach the top-most rivet in 3 of the 4 wingwalk ribs. (The other open hole in each of the rib attach points needs to wait for the flap brace.)

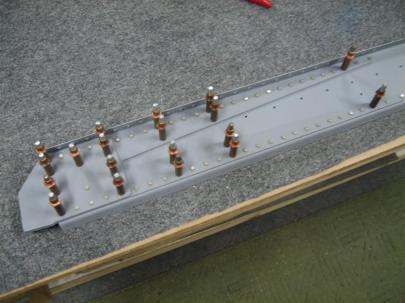

I moved my way outboard from there, two rivets in each rib.

Halfway there, I bent over both of the rivets in the aileron pushtube doubler area, and drilled both of those rivets out. Then, the aileron gap seal switches “open” rivets (compared to the flap brace) so of course I set a two rivets there that had to be drilled out.

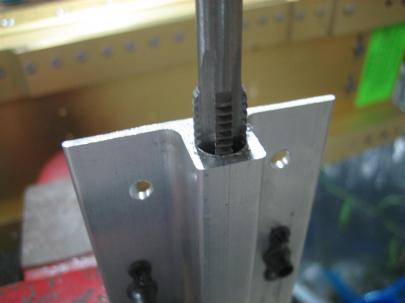

When I got to the end, I noticed things weren’t lining up very well.

I still couldn’t reach the one rivet (shown on the left here), but I got the other 3 set properly.

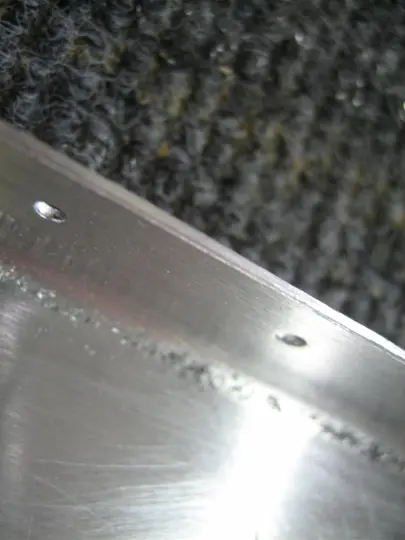

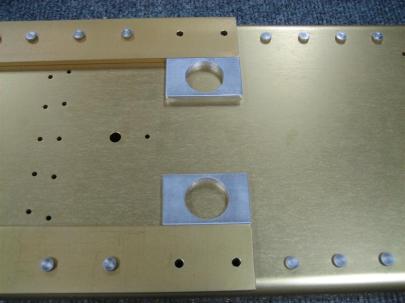

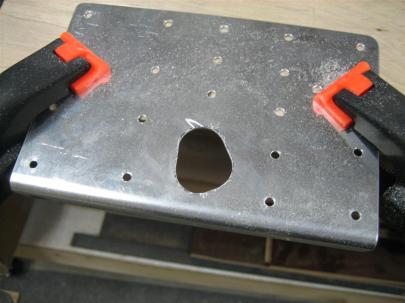

Let me bring you back to the very first rivet I set. The camera is upside down here (so the part is right side up).

The upper, leftmost rivet bent over (it was the first one I set with the economy squeezer). After drilling out, the hole was englarged.

With only slightly enlarged holes, sometimes you can just squeeze another rivet (a little longer this time) and it will expand to fill the hole nicely.

This one did not properly expand, and by the time the shop head was formed, it kind of formed in the hole.

Hmm. I know this is a critical piece, so I’m going to have to call Van’s and ask them what the best course of action here is.

I’m hoping I can step up to a AN470AD5-9 rivets, but I’ll need to drill the rivet and hole out to 5/32″ and I’m worried about edge-distance in the up direction.

We’ll see what the guys at Van’s have to say.

January 31st update: Ken S at Van’s wrote back.

A 5 rivet should work ok. If you can fill the hole with the original rivet, that’s ok too –even with

a slightly undersize head. Just be sure that the rivet engages the entire circumference of the

hole.

Alright. I’ll have to add AN470AD5- rivets to my next order from Van’s or Aircraft Spruce. In the meantime, I’m going to keep working on other stuff.

1.5 hours and 28 stupid rivets set (my arms are tired from the economy squeezer); 8 of those drilled out.

I’m going to have to buy a new yoke ($$$) and probably do some surgery on the offending rivet in the last picture.

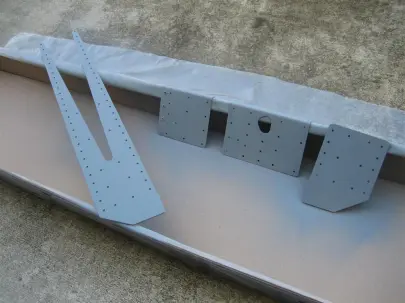

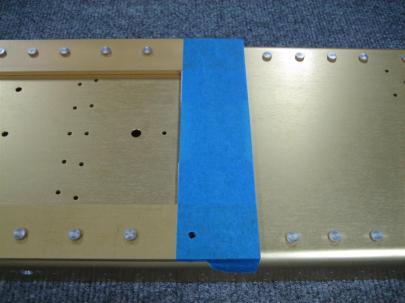

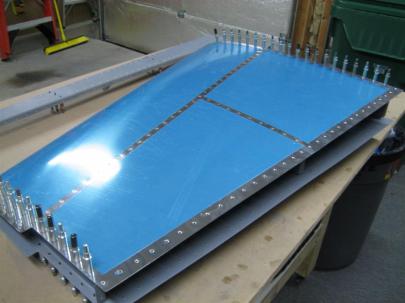

I’m stopping this post and starting another one (click next below) because I moved on to the skins. I really needed to end on a good note today, and the skins actually did the trick.

Posted by Andrew

Posted by Andrew